The concept of self-repairing technology has moved from science fiction to laboratory reality in the field of electronics. Researchers and engineers are making significant strides in developing circuits that can detect and repair their own damage without human intervention. This emerging field of self-healing circuit monitoring promises to revolutionize everything from consumer electronics to critical infrastructure systems.

Self-healing circuits represent a fundamental shift in how we approach electronic reliability. Traditional circuits fail when damaged - a broken connection or compromised component typically renders the device useless until repaired. The new generation of smart materials and monitoring systems enables electronics to autonomously respond to physical damage, electrical faults, or performance degradation.

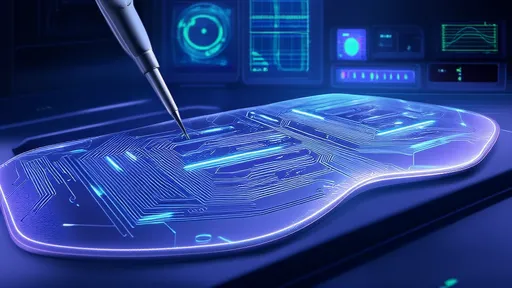

At the heart of this technology lies a sophisticated monitoring system that continuously evaluates the circuit's health. Tiny sensors distributed throughout the circuit board measure electrical characteristics like resistance, capacitance, and signal integrity. These measurements create a real-time map of the circuit's condition, allowing the system to detect anomalies that indicate potential or actual damage.

What sets self-healing systems apart is their ability to respond to detected issues. When the monitoring system identifies a problem, it triggers one of several repair mechanisms depending on the nature and severity of the damage. For minor conductive pathway breaks, microcapsules containing conductive materials can rupture to bridge gaps. More sophisticated systems use shape-memory alloys that return to a predetermined configuration when heated, effectively "closing" breaks in circuits.

The applications for this technology span numerous industries. Aerospace engineers see particular promise in self-healing avionics, where circuit failures during flight can have catastrophic consequences. NASA has been experimenting with these systems for spacecraft that operate in environments where manual repairs are impossible. Similarly, medical device manufacturers are exploring how self-repairing circuits could improve the reliability of implantable electronics like pacemakers and neural stimulators.

Consumer electronics stand to benefit significantly as well. Imagine smartphones that repair their own cracked circuitry or laptops that maintain peak performance despite minor liquid damage. While current implementations remain costly for mass-market products, the technology is progressing toward commercial viability. Several major electronics manufacturers have quietly filed patents related to self-healing circuit technologies, suggesting we may see these features in consumer devices within the next decade.

Environmental factors pose one of the biggest challenges to electronic reliability, and self-healing circuits offer promising solutions. In humid conditions where corrosion threatens traditional circuits, self-healing systems can detect and isolate corroded areas while maintaining functionality through redundant pathways. For electronics exposed to extreme temperatures, shape-memory materials and adaptive components can compensate for thermal expansion and contraction that would normally cause failures.

The development of these systems requires interdisciplinary collaboration. Materials scientists work on novel conductive polymers and microencapsulated healing agents. Electrical engineers design the monitoring networks and failure prediction algorithms. Computer scientists develop the machine learning systems that enable circuits to distinguish between temporary anomalies and genuine failures requiring intervention.

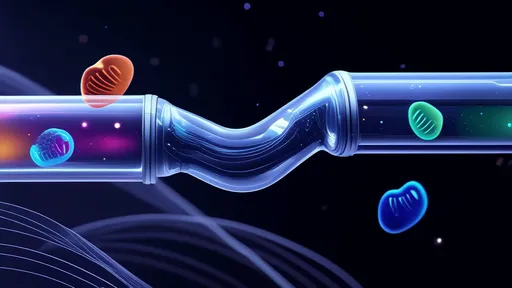

One particularly innovative approach involves borrowing concepts from biological systems. Researchers are studying how neural networks and biological cells repair themselves to inspire electronic self-healing mechanisms. Some experimental systems now incorporate fluidic channels that distribute healing agents similarly to how blood carries repair factors throughout the body. These bio-inspired designs show remarkable resilience to various types of damage.

Reliability testing has revealed both promise and limitations of current self-healing circuit technology. While these systems excel at addressing certain types of damage like micro-fractures and minor corrosion, they still struggle with catastrophic damage or multiple simultaneous failures. The healing mechanisms also typically work for a limited number of repair cycles before being exhausted. Researchers are working on systems that can draw from larger reservoirs of healing materials or create entirely new conductive pathways when needed.

The economic implications of widespread self-healing circuit adoption could be substantial. While initial costs are higher than conventional electronics, the potential reduction in warranty claims, repairs, and premature replacements might justify the investment for many applications. Industries with high failure costs, like aerospace and medical devices, may be early adopters even at premium prices.

Looking ahead, the next generation of self-healing circuits may incorporate even more advanced features. Some researchers envision circuits that can physically reconfigure themselves to bypass damaged areas entirely. Others are working on systems that can harvest energy from their environment to power the healing process indefinitely. The combination of self-healing circuits with other emerging technologies like flexible electronics and biodegradable substrates could open up entirely new application areas.

As with any transformative technology, self-healing circuits raise new questions about standardization and certification. Regulatory bodies will need to develop new frameworks for evaluating and approving these systems, particularly in safety-critical applications. There are also intellectual property considerations, as companies race to patent various aspects of the technology.

The journey from laboratory prototypes to mainstream adoption will undoubtedly present challenges. Manufacturing processes need to adapt to incorporate healing materials and monitoring systems without significantly increasing production complexity. Designers must learn new principles for creating circuits that can effectively leverage self-healing capabilities. Yet the potential benefits for reliability, sustainability, and performance make this technological direction compelling.

In the broader context of technological evolution, self-healing circuits represent more than just an incremental improvement. They embody a shift toward more resilient and autonomous systems that can maintain functionality despite real-world challenges. As the Internet of Things expands and electronics penetrate ever more aspects of our lives and infrastructure, the ability to self-repair could become not just advantageous but essential.

While significant hurdles remain before we see self-healing circuits in everyday devices, the pace of progress suggests this technology will play an important role in electronics' future. From extending product lifespans to enabling electronics to operate in harsh environments, the applications are as diverse as they are impactful. The coming years will likely see self-healing progress from laboratory curiosity to practical solution, changing our expectations of what electronics can endure.

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025