The concept of turning organic matter into electricity might sound like science fiction, but microbial fuel cells (MFCs) are making it a reality. These innovative bioelectrochemical systems leverage the metabolic activity of bacteria to produce energy while simultaneously treating wastewater. Unlike traditional fuel cells that rely on chemical reactions, MFCs operate through biological processes, offering a sustainable alternative for power generation and environmental remediation.

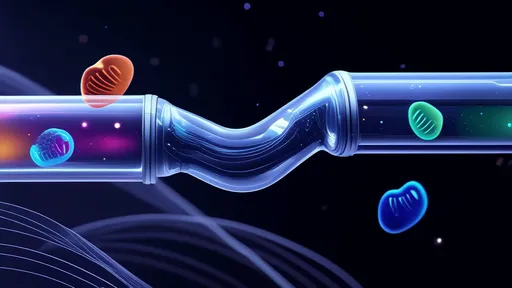

At the heart of an MFC lies a simple yet elegant principle: certain bacteria, known as exoelectrogens, can transfer electrons extracellularly during their metabolic breakdown of organic compounds. When these microbes consume substrates like glucose or acetate in the anode chamber, they release electrons and protons. The electrons travel through an external circuit to the cathode, creating an electric current, while the protons migrate through a proton exchange membrane to complete the circuit. This continuous flow of electrons constitutes usable electricity harvested from microbial activity.

The environmental implications of this technology are profound. Conventional wastewater treatment plants consume significant amounts of energy to break down organic pollutants. MFCs flip this paradigm by extracting energy from the waste itself. Early pilot projects have demonstrated that MFC systems can achieve 80-90% organic removal while generating power, potentially transforming treatment plants from energy consumers to energy producers. Researchers at the University of Queensland recently reported a scaled-up MFC configuration that powered small sensors continuously for six months using only brewery wastewater as fuel.

Recent advancements in electrode materials have dramatically improved MFC performance. Carbon-based nanomaterials, such as graphene oxide and carbon nanotubes, have shown exceptional conductivity and biocompatibility, enhancing electron transfer between bacteria and electrodes. Meanwhile, innovative membrane-less designs and stacked configurations are addressing historical challenges of internal resistance and low power density. A team at Penn State University achieved a breakthrough by developing a paper-based MFC that costs less than $1 to produce, opening possibilities for disposable biosensors in remote areas.

Beyond wastewater treatment, MFCs are finding unexpected applications. In sediment MFCs deployed in marine environments, naturally occurring bacteria generate enough power to operate environmental monitoring buoys. Medical researchers are exploring implantable MFCs that could power pacemakers using glucose from bloodstream. Perhaps most intriguing are plant-MFC hybrids where root exudates feed electrogenic bacteria, creating living solar panels that generate electricity from photosynthesis byproducts. Dutch scientists have successfully operated outdoor systems producing 0.4 W per square meter of plant growth - enough to charge mobile devices in wetland areas.

The scalability of MFC technology remains a subject of intense research. While laboratory-scale units reliably produce milliwatts of power, commercial implementation requires overcoming hurdles like inconsistent microbial communities and long-term stability. However, modular designs where multiple MFC units operate in parallel show promise for larger applications. A pilot plant in Indonesia currently treats palm oil mill effluent while powering its own monitoring systems, demonstrating the technology's industrial potential. As genetic engineering advances, tailored microbial consortia may further boost power outputs by optimizing electron transfer pathways.

Economic analyses suggest MFCs could achieve cost-competitiveness within the decade. When factoring in energy savings from wastewater treatment and potential byproduct recovery (like hydrogen gas or desalinated water), the total value proposition becomes compelling. The global market for bioelectrochemical systems is projected to grow at 9.8% annually, driven by increasing wastewater treatment demands and renewable energy mandates. Startups like Cambrian Innovation already offer commercial MFC systems for industrial clients, signaling the technology's transition from lab curiosity to practical solution.

As climate change accelerates the search for carbon-neutral technologies, microbial fuel cells represent a rare convergence of environmental sustainability and energy innovation. By harnessing the ancient metabolic processes of microorganisms, we may have found a way to turn pollution into power - one bacterium at a time. The coming years will determine whether this promising technology can overcome its scaling challenges to become a mainstream contributor to the renewable energy mix.

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025