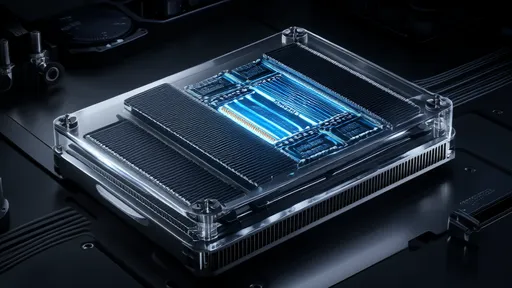

As data centers continue to expand in both size and computational power, the demand for efficient cooling solutions has never been higher. Traditional air-cooling methods are increasingly being replaced by more advanced techniques, with immersion cooling emerging as a frontrunner. This method, which involves submerging hardware in a thermally conductive dielectric fluid, offers superior heat dissipation compared to conventional systems. However, one critical aspect that often goes overlooked is the reclamation and recycling of these specialized cooling fluids.

The process of immersion cooling fluid reclamation is not just about environmental responsibility—it's a crucial component of operational efficiency and cost management. These dielectric fluids, while highly effective, represent a significant investment for data center operators. The ability to purify and reuse these liquids can dramatically reduce long-term expenses while minimizing the ecological footprint of large-scale computing facilities.

Understanding the Composition of Immersion Cooling Fluids

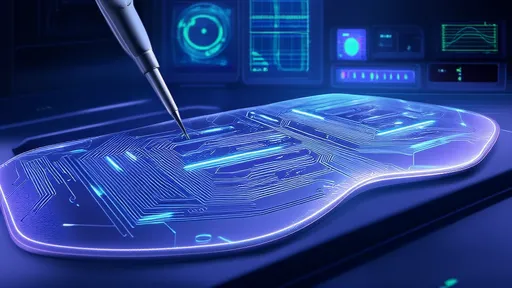

Modern immersion cooling fluids are typically formulated from synthetic or mineral-based dielectric compounds engineered to provide optimal thermal transfer while remaining electrically non-conductive. These specialized liquids are designed to withstand prolonged exposure to high temperatures and electronic components without breaking down or losing their essential properties. However, over time, even the highest quality fluids will accumulate microscopic particulate matter, dissolved gases, and potential contaminants that degrade performance.

The degradation process occurs gradually as the fluid circulates through the system, picking up minute amounts of material from components, seals, and gaskets. Additionally, thermal cycling can cause subtle chemical changes in the fluid's composition. While these changes might not be immediately apparent, they eventually reduce the fluid's heat transfer efficiency and could potentially lead to increased maintenance requirements for the submerged equipment.

Current Reclamation Technologies and Methods

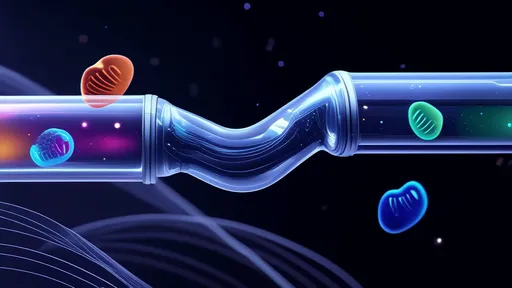

Several approaches have emerged for restoring used immersion cooling fluids to near-original condition. Centrifugal separation remains one of the most common first-stage processes, effectively removing larger particulate matter from the fluid. This mechanical method is often followed by finer filtration stages that can capture particles down to the sub-micron level. For more comprehensive reclamation, some systems incorporate distillation processes that separate the base fluid from accumulated contaminants.

Advanced facilities now employ multi-stage reclamation systems that combine mechanical, chemical, and sometimes even electrostatic purification methods. These systems can extend the usable life of immersion cooling fluids by several cycles, significantly reducing the need for complete fluid replacement. Some progressive data centers have implemented on-site reclamation units that continuously process small volumes of fluid, maintaining optimal quality throughout the cooling system's operation.

The Economic Case for Fluid Reclamation

While the initial investment in reclamation equipment may seem substantial, the long-term financial benefits are compelling. High-quality immersion cooling fluids can cost thousands of dollars per gallon, and a typical data center might require hundreds or even thousands of gallons to fill their systems. By implementing an effective reclamation program, operators can reduce their fluid replacement costs by 60-80% over the lifespan of their equipment.

Beyond direct fluid savings, reclamation also contributes to reduced downtime and maintenance costs. Cleaner fluid means less wear on pumps and filtration systems, fewer instances of component fouling, and more consistent cooling performance. These factors combine to create a strong return on investment that often justifies the reclamation system's cost within the first few years of operation.

Environmental Considerations and Sustainability

The environmental impact of immersion cooling fluid disposal has become an increasingly important concern for the data center industry. Many of these specialized fluids, while safe during use, require careful handling when being retired. Improper disposal can lead to soil and water contamination, creating regulatory challenges and potential liability issues for operators.

Fluid reclamation directly addresses these environmental concerns by dramatically reducing the volume of waste generated. A well-designed reclamation system can extend the useful life of cooling fluids by five to ten times compared to single-use scenarios. This reduction in waste volume not only benefits the environment but also simplifies regulatory compliance and reduces disposal costs for data center operators.

Technical Challenges in Fluid Reclamation

Despite its advantages, immersion cooling fluid reclamation isn't without its technical hurdles. One significant challenge lies in maintaining the fluid's precise chemical composition throughout multiple reclamation cycles. Some additives that enhance thermal performance or inhibit corrosion may be depleted during use and must be carefully replenished during the reclamation process.

Another challenge involves detecting and removing contaminants that don't respond to standard filtration methods. Certain types of dissolved materials or chemical byproducts may require specialized treatment processes. Developing accurate testing protocols to verify fluid quality after reclamation remains an area of ongoing research and development within the industry.

Industry Trends and Future Developments

The immersion cooling fluid reclamation market is evolving rapidly as more data centers adopt liquid cooling solutions. We're seeing increased collaboration between fluid manufacturers, equipment providers, and data center operators to develop more efficient reclamation technologies. Some companies are experimenting with "closed-loop" systems where fluid is continuously purified without ever being removed from service.

Emerging technologies like nanotechnology-based filtration and advanced spectroscopic analysis for fluid quality assessment promise to make reclamation processes even more effective in the coming years. There's also growing interest in developing "self-healing" fluids that can automatically repair certain types of molecular degradation without requiring external processing.

Implementation Strategies for Data Centers

For data centers considering immersion cooling with fluid reclamation, a phased approach often yields the best results. Many operators begin with a small-scale pilot system to evaluate different reclamation methods before committing to full implementation. This allows for the assessment of various technologies and the development of customized solutions tailored to specific operational needs.

Successful implementation also requires careful staff training and the development of proper handling procedures. While immersion cooling systems are generally safe when properly maintained, working with reclamation equipment requires additional safety considerations and operational protocols. Many leading data centers have found it beneficial to establish dedicated fluid management teams to oversee all aspects of their reclamation programs.

Regulatory Landscape and Standards Development

As immersion cooling becomes more prevalent, regulatory bodies are beginning to establish guidelines for fluid handling and reclamation. Various industry groups are working to develop standardized testing methods and quality benchmarks for reclaimed fluids. These standards will help ensure consistency across the industry and provide data center operators with clear metrics for evaluating reclamation system performance.

Looking ahead, we can expect to see more stringent regulations regarding fluid lifecycle management. Forward-thinking data centers are already positioning themselves by implementing reclamation programs that exceed current requirements, anticipating future regulatory trends in environmental responsibility and resource conservation.

The Path Forward for Sustainable Cooling

Immersion cooling fluid reclamation represents more than just a technical solution—it's a fundamental shift in how the data center industry approaches resource utilization. By closing the loop on cooling fluid lifecycle management, operators can achieve significant cost savings while dramatically reducing their environmental impact.

As the technology continues to mature, we can expect reclamation systems to become more sophisticated, more efficient, and more widely adopted. What begins as an optional enhancement may soon become an industry standard, driven by both economic imperatives and environmental responsibility. For data centers looking to future-proof their operations while improving their bottom line, immersion cooling fluid reclamation offers a compelling solution that addresses multiple challenges simultaneously.

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 26, 2025

By /Aug 15, 2025